CNC multi-axis machining is an entire machining technique. The tool can shift in 4 or maybe more directions. Multi-axis CNC machining permits the production of intricate parts employing different cutting tools and solutions, like milling, waterjet cutting, and laser cutting.

The price of CNC precision machining generally is a bit greater than for common machining strategies. Even so, the benefits the procedure presents make it definitely worth the more investment decision. Below are some of These benefits:

The principle of repeatability is one of the significant foundation stones for modern manufacturing industries. Each component created by a method is meant to appear like just about every other part for your conclude user.

You will find a collection of assets down below, or you are able to head to our understanding hub and filter on CNC machining case studies, in-depth structure guidelines, and explanations of various surface area finishes.

Soon after getting instructed on the information gathered for this report, he acknowledged the shipments final year but claimed they associated parts which were not subject matter to export controls.

Whilst CNC precision machining may very well be required for distinct features and dimensions, necessitating CNC precision machining when ordinary machining tolerances would suffice can be quite a massive waste of sources.

“According to the Directions you put into the machine, you can also make the firing pin of a rifle or maybe a metal water bottle from a block of metal. They take away human mistake and enhance productiveness. ”

The robotics and automation sector has occur a great distance but remains to be in its early stages due to the unlimited prospects in the area. CNC machining presents the ways to meet these opportunities by generating click here parts that serve the function needed. Some of these parts are:

The computer-controlled machines are used to the complex and precise manufacturing that's vital in lots of industries, which includes weapons production.

There's no definite Price tag for precision machining since fees differ determined by numerous factors. CNC machining has many distinctive components, Every single which has a diverse price. As an example, the quantity of axes is usually selected in precision machining equipment.

Product expenses is often reduced by thinking about the scale of the blank necessary, and the associated fee and machinability of the majority substance (softer alloys are faster to machine).

A CNC machine replaces human labor with Laptop numerical Command systems and gets rid of the human error risk variable involved with the cutting processes. Workers might be transferred to more talent-intensive roles such as CNC style and design operations.

The applications of CNC machining while in the aerospace industry are huge and trusted. Many of the machinable aerospace parts incorporate engine mounts, fuel flow factors, landing equipment elements, and fuel obtain panels.

Though the usage of CNC for semiconductors has been described above in applications of electronics and smartphones, the particular usage of CNC systems inside the industry is much wider.

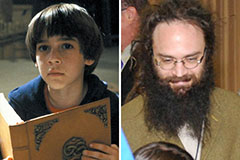

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Barret Oliver Then & Now!

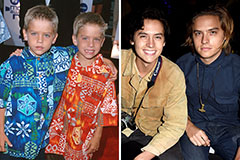

Barret Oliver Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Christina Ricci Then & Now!

Christina Ricci Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!